Arandelas espirales

-

Upload

ismael-vieito-rana -

Category

Documents

-

view

219 -

download

0

Transcript of Arandelas espirales

-

7/21/2019 Arandelas espirales

1/2

Advancing Technology-Simplifying Your Testing

By applying a preload to the stud which is higher than the actuators operating range, theload train will be subjected to only a static, not cyclical load. DTE uses spiral washers on

all actuator connections larger than 5500 Lb. (25kN).

Preloading the system:

Relieve all static pressure from the actuator

Clean and grease the stud and the threads in the connecting parts.

Turn the stud into the actuator rod; insert the spiral washers on the stud with the

Spiral Washers

Purpose of Spiral Washers

Spiral washers are designed for use with a stud

for creating a fatigue rated connection from

the actuator to load carrying elements such

as load cells, ball joints and swivels.

Theory of Operation

A fatigue rated connection is dened, as a con-

nection that is preloaded above the cyclical

load value, therefore the connection is notsubjected to fatigue. Traditionally, the fatigue

rated connection is viewed as two springs in

parallel, the stiff spring is the spiral washer

and the softer spring is the stud.

FATIGUE

LOAD

Spiral washersare

stiff spring incompression.

Load changes have

no affect due to large

area. Stud is soft spring in tension.

Load on stud does not change

signicantly due to its resilience.

-

7/21/2019 Arandelas espirales

2/2

DYNAMIC TESTING & EQUIPMENT Spiral Washers

spiral surface facing each other. Turn them until closed.

Attach the connecting unit (grips; swivel, other xture), make sure, that the stud is atleast one diameter length in the unit.

Connect actuator into a force train or a suitable xture, apply a static force (Adjusthydraulic power unit pressure to 3300 psi) and lock the washers with spannerwrenches.

The open space on the washers should not exceed 30 deg. from the closed position. To disassemble the connection, reverse the process.

Call DTE engineering if you have questions with the installation. Below part numberspecies one pair of identical washers.

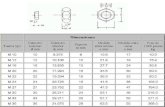

SPIRAL WASHERS

NUMBER --NUMBER STUD SIZE OD STROKE

60811

-001 5/8

2.75 .03

-002 M16

-003 M18

-004 3/4

-005 M20-006 7/8

-007 M24

-008 1

-009 M27

-010 1 1/8

-011 M30

-012 1 1/4

-013 M32

60966

-001 1 1/4

33/4

.04

-002 M33

-003 1.5-004 M38

-005 M42

-006 2

-007 M50

64452-002 2

8.75 .06-003 M72

62252

-001 2.5

8.75 .06

-002 M72

-003 2.75

-004 3

-005 M90

Black Oxide standard

Specify Electroluss Nickel

Plating for high humidity

environments

All specications subject to change without notice.

Please refer to Technical Bulletin SPW-TB for further information.