CELDA DE FLOTACION.pdf

-

Upload

milena-lemus-fonseca -

Category

Documents

-

view

215 -

download

0

Transcript of CELDA DE FLOTACION.pdf

-

8/12/2019 CELDA DE FLOTACION.pdf

1/2

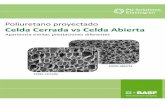

Vessel description & operationThe Tridair Hydraulic Induced GasFlotation Cell typically accomplishes up to9098% removal of insoluble oil/organicand suspended solids. Removal efficiencyis influenced by physical characteristics ofthe incoming stream such as pH, totaldissolved and suspended solids,temperature, presence of chemicals,mixtures of different streams and Zeta

Potential.

How it worksThe vessel is divided into four flotationcompartments, each separated by a seriesof over and under baffle plates. Thearrangement of baffle plates permits flowsurges up to 25% without loss of removalefficiency.

As the water leaves the flotationcompartment, it enters a smaller cleanwater chamber. From this clean water

compartment, a centrifugal pumprecirculates the water through a header toa downcomer in each cell. Located ineach downcomer is a singlenozzle/eductor system.

Gas is induced through a controllingstainless steel needle valve to theeductors. The unique nozzle/eductor

Tridair Hydraulic IGF

Tridair Hydraulic induced gas flotation removes up to

98% of insolubles and solids

Issue 2 02.07 Page 1975-A1

design ensures even dispersion of thefinely divided air/gas bubbles throughoutthe liquid. By controlling the volume andrate of air/gas induced, the developmentof the proper bubble size for the efficientlifting of oil/organic and suspended solidsis achieved.

Most of the oil/organic contained in thewaste water stream is in the form of areversed emulsion. Suspended solids areusually oil/organic wet particles, metaloxides, etc. Both oil/organic andsuspended solids are of such a densitythat they will float when they areattached to the minute dissolved bubbles.

Oil/organic and suspended solidsaccumulate on the surface of the liquid as

a froth, where they are continuouslyremoved from the flotation compartmentby means of a gravity spill over andadjustable weir.

CleanWaterOutlet

OilSkimming

Outlet

Oily SolidsOutlet

Tridair Hydraulic installation skid mounted

General schematic for Tridair Hydraulic

-

8/12/2019 CELDA DE FLOTACION.pdf

2/2

Tridair Hydraulic IGF

Issue 2 02.07 Page 1975-A2

Applications Oilfield produced water, offshore and

onshore Refining/petrochemical waste water

Recycle/reuse Discharge

Boiler feed water treatment

Features Hydraulic gas induction High gas to water ratios Numerous skimming methods available Pressurized operation Cylindrical vessels

Benefits Few moving parts Oil removal efficiencies to 98% Minimize oil skimmings Eliminate VOC emissions

Minimize solids fouling

Approximate size Approximate

Model Flow rate 3PH Feet- Feet- Feet- weight

Number GPM BWPD 440 VAC Inches Inches Inches Pounds x1000

(1000) HP L W H Dry Wet

DL-5 15 500 1 7'-6" 3'-6" 3'-0" 2 4.5

DL-10 29 1,000 2 11'-0" 4'-0" 3'-9" 5 7.5DL-30 88 3,000 3 12'-0" 5'-9" 5'-6" 5.5 9.5

DL-50 146 5,000 5 15'-0" 6'-0" 6'-9" 8 15

DL-100 292 10,000 7.5 15'-6" 6'-9" 7'-0" 10 24

DL-150 438 15,000 15 20'-0" 8'-6" 8'-0" 12 35

DL-200 583 20,000 20 20'-6" 9'-0" 9'-0" 15 42

DL-250 729 25,000 25 20'-6" 10'-0" 9'-9" 18 50

DL-300 875 30,000 25 21'-6" 10'-9" 10'-0" 25 78

DL-400 1167 40,000 35 24'-0" 13'-6" 10'-0" 35 125

DL-500 1458 50,000 50 23'-0" 14'-0" 12'-0" 40 140

DL-750 2188 75,000 75 25'-0" 16'-0" 13'-0" 45 160

DL-1000 2917 100,000 100 33'-0" 18'-0" 14'-0" 50 180

L

H

W

NATCO Head OfficeHouston, USA

Tel: +(1) 713 849 7500

Email: [email protected]

NATCO UK

Farnborough, UK

Tel: +(44) 1252 363000

Email: [email protected]

NATCO JapanTokyo, Japan

Tel: +(81) 33288 1901

Email: [email protected]

NATCO Canada

Calgary, Canada

Tel: +(1) 403 236 1850

Email: [email protected]

NATCO(Scomi NATCO Joint Venture Company)

Kuala Lumpur, Malaysia

Tel: +(60) 3 2168 4382

Email: [email protected]

www.natcogroup.com

For more information on the NATCO Tridair Hydraulic IGF or other NATCO Group products contact:

![Celda de flotacion de Laboratorio EDEMETid85]1.pdf · Title: Celda de flotacion de Laboratorio EDEMET Author: EDEMET Subject: Celda de flotacion Keywords: celda de flotacion; concentracion](https://static.fdocumento.com/doc/165x107/5ba4202109d3f2c0278ce248/celda-de-flotacion-de-laboratorio-id851pdf-title-celda-de-flotacion-de-laboratorio.jpg)