HubbelArresterLeadLength[

-

Upload

jahosolaris5512 -

Category

Documents

-

view

228 -

download

0

Transcript of HubbelArresterLeadLength[

-

7/30/2019 HubbelArresterLeadLength[

1/4

ARRESTERS

ARRESTERLEADLENGTHDefinition and Importance in Surge Protection of Distribution Systems

he first step in reducingvoltage stress to extend thelife of insulated equipmentis the use of MOV arresterswhich have lower discharge

T

Figure 1

voltage levels than silicon-carbide(SiC) designs. The 50 year old SiCdesign is still being produced by somemanufacturers, and some utilities stilluse SiC arresters for the protection ofpole-mounted transformers. However,most utilities have switched to MOVarresters for the protection of themore critical, and costly to replace,portions of their systems. The nextstep is the use of optimum connectionmethods for the arrester lead wires.

The highest surge voltage stress occurswhen lightning strokes to the over-head line have fast rates-of-rise. Anarrester discharge current whichreaches its crest in 1 sec will produce10% more voltage across an MOVarrester, and 30% more voltage acrossa SiC arrester, than will the standard 8sec test waves used to establish thecomparative IR discharge voltage datashown in arrester catalogs. Adding tothe surge voltage across the arrester is

the L di/dt inductive voltage drop inlead wire carrying the surge current.Wire inductance (L) is a constant,typically 0.4 microhenries per foot.The surge current rate-of-rise (di/dt)varies with each lightning stroke

-

7/30/2019 HubbelArresterLeadLength[

2/4

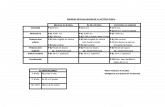

*Margin based on BIL. Others based on CWW.Table 1

Table 2

Table 3

Table 4

discharge. Multiplying the two quantities gives an induc-tive drop in kV per foot of wire. For example, a 10 kAdischarge current cresting in 1 sec makes di/dt = 10 kA/sec, and produces a lead wire drop of 0.4 x 10 = 4 kV/

foot. If the 10 kA surge took 8 sec to crest, the inductivedrop would be only 0.5 kV/foot.

It is now known that fast-rising arrester discharge currentsare much more common than previously believed. Prior to1980, lightning induced arrester discharges with rates-of-rise above 4 kA per microsecond had been measured, butwere thought to be a low probability event that could besafely ignored in practice. In the late 1970s, more accuratemeasurements of arrester surge currents were taken whichshowed rates-of-rise at 13 kA/sec in half of the dis-charges, with a maximum value of 60 kA/sec. Consistentwith this relatively new data, a realistic estimate for the

lead wire voltage drop in arrester installations exposed tolightning is 6 kV/foot - this value is now used for calculat-ing the protective margins under fast-front surge condi-tions.

Protective margin is the percent by which equipmentinsulation strength exceeds maximum surge voltageallowed on the system by the arresters. Insulation strengthis the BIL (Basic Insulation Level) for surges cresting inthe 8 sec time region (slow lightning), and CWW(Chopped Wave Withstand) for surges cresting in theregion under 2 sec (fast lightning) for oil filled insula-tion. CWW is typically 15% higher than BIL for a givensystem. For cable, the CWW is assumed equal to the BILto be conservative. Protective margin is determined bycomparing insulation strength with maximum surgevoltage - looking at both time regions and taking thesmaller of the two margins as the realized overvoltageprotection for the system.

APPLICATION

Overhead transformers are well protected with tankmounted arresters, because this installation methodvirtually eliminates series arrester leads. However, many

URD installations use arresters mounted as shown inFigure 1. This construction practice is quite common.Such installations tend to have very long arrester leadswhich greatly increase surge voltage stress on switch andcable insulation. Arrester lead is the combined length of

-

7/30/2019 HubbelArresterLeadLength[

3/4

Figure 3

Figure 2

Figure 4

line and ground lead wire in serieswith the arrester AND in parallelwith the protected device (trans-former in this case).

Figure 1 shows an installation withsignificant series arrester lead on theline side. The length of lead wire from

the top of these arresters to the switchis about 4 feet. Thus, the line lead of4 feet can be expected to add 24 kVto the arrester voltage during fast-front lightning surges.

The protective margin of the Figure 1installation could be greatly improvedby moving the line connection insuch a way as to make the connectionto the arrester first then to the switch.

Table I shows how the protectivemargins in an overhead pole-mountedinstallation varies with various distribution arrester typesand lead lengths. ND and HD abbreviations designateNormal Duty and Heavy Duty arresters.

Utility studies of URD system performance have shownthat reliability is increased by reducing surge voltage stresson transformers and cable. Surge voltage stress damage tostandard URD cable is cumulative. Unlike transformerinsulation, most solid dielectric cable insulation has amemory. Each voltage impulse contributes to deteriora-tion and ultimate cable

failure. Cable manufac-turers are improvinginsulation compoundsto retard this cumulativedamage effect. However,for the many miles ofcable now installed,maximum service lifecan be achieved byreduction of unneces-sary overvoltage stress.

Surge voltage waves

travel through the cableat 500 feet/sec, abouthalf the speed of light.When a surge reaches a

point of high impedance such as anopen switch or transformer, it reflectsupon itself, like a wave of waterhitting a seawall. This doubles thevoltage at the reflection point, andalong the cable, as the incoming andreflective waves overlap. Even with anarrester at each high impedance point

in the system, some reflection occursin the short time it takes an arrester toturn on and begin limiting voltage.With an MOV arrester at the highimpedance point, these partialreflections are roughly equal to 1.3times the arrester's MCOV rating. Ineither case, it is important to mini-mize surge voltage allowed into thesystem by installing, with shortconnecting leads, a low dischargearrester at the riser pole junctionbetween overhead line and cablesystem terminator.

On 15 kV distribution systems, a good arrester at the riserpole may provide all the surge protection economicallyjustified based on the individual utilitys experiencewith cable system reliability. On 35 kV systems insulatedat only 150 kV BIL, adequate surge voltage protectioncannot be achieved unless any high impedance reflectionpoints are equipped with arresters, or eliminated by usingloop feed construction with no open points.

Tables 2 and 3 compare

protective marginsrealized on two differentURD systems, 13.2 and24.9 kV, using threedifferent arrester types.The RP abbreviationdesignates a Riser Polearrester specificallydesigned for such appli-cations. The 24.9 kVexamples in Table 4 havearresters at the reflectionpoints in addition to

those on the riser pole.These examples are basedon severe, but common,fast-front lightning

-

7/30/2019 HubbelArresterLeadLength[

4/4

view fromVol. 2, No. 1 January 1996

TiPS NEWS&

SUMMARY

The key to installing arresters, to utilize their full protective capabilities, is tofollow this procedure as closely as possible:Carry the line and ground connections to the arrester terminals first, andthen on to the terminals of the protected equipment. This applies to over-head and underground installations. With underground systems, where surge

voltages cause cumulative damage in most solid dielectric cable, and protectivemargins are reduced by voltage reflections, it is imperative to keep arrester leadlength as short as possible.

LEAD LENGTH CALCULATION

The inductive voltage drop in lead-wire carrying surgecurrent is a function of lead wire inductance. L (typically0.4 H/ft), and the rate of rise of the surge current di/dr.Thus V = (L) (di/dr)

(a) Using a 6 ft. lead wire and 8/20s, 10 KA surgecurrent:

V = Voltage drop / ft. lead lengrh= L di/dt = 0.4 H/ft. x 10KA/8 Sec.= 0.4 x 10-6H/ft x 10kA/8 x 10-6 Sec.= 0.5 kV/ ft.

Therefore, for a 6 ft. long lead, the voltage drop willbe 0.5 x 6 = 3 kV.

(b) Using a 6 ft. lead wire and a fast rising surge current,10kA cresting in 0.5 sec. For example:

V = 0.4 H / ft. x 10 KA/ 0.5 Sec.= 8 kV/ ft.

Therefore, for a 6 ft. long lead, the voltage drop willbe 8 x 6 = 48 kV.

discharges which produce 6 kV/ft.inductive voltage drop in seriesarrester leads. Note the dramaticimprovement in protective marginwhen lead length effect is minimizedor eliminated. Protective marginexamples in Tables 2 through 4 allowfor some memory effect loss of cable

insulation strength by assumingCWW is equal to system BIL.

Figure 2 shows an arrester installationwhich corresponds to the 2' Leadexamples in Tables 2 through 4.Again, arrester lead is the combinedlength of line and ground lead wire inseries with the arrester AND inparallel with the protected device(cable terminator in this case). Or inother words, arrester leads are thosewires which carry surge currentthrough the arrester AND are con-nected across the terminator.

Figure 3 shows a similar installationexcept with line connection taken tothe arrester and then to the termina-tor. This installation eliminates allarrester lead on the line side since theline connection wire carrying surgecurrent through the arrester is not inparallel with the cable terminator.

The Figure 4 installation takes Figure3 one step further by mounting thearrester between terminator and poleground so the ground lead can becarried to the arrester first and then tothe base of the terminator. Thisconnection method eliminates allarrester lead and corresponds to theO Lead examples in Tables 2through 4. Here, no surge currentflows in either line or ground leadsbetween arrester and terminator.Thus, surge voltage on the cable

terminator is minimized since the 111protective benefit of the arrester isseen by the cable system.

Fax 573-682-8714 http://www.hubbellpowersystems.com

POWERSYSTEMS, INC.

Copyright 2004 Hubbell 210 North Allen Street Centralia, MO 65240

NOTE: Because Hubbell has a policy of continuous product improvement, we reserve the right to change design and specifications without notice.

EU1509-WB