MANUFACTURA_GENERALIDADES

-

Upload

tlatuani1000 -

Category

Documents

-

view

215 -

download

0

Transcript of MANUFACTURA_GENERALIDADES

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

CHAPTER 5: Manufacturing

McGraw-Hill/Irwin

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• The quality imperative• Manufacturing perspective• Manufacturing strategy• Contemporary

manufacturing developments

Overview of manufacturing

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

The 8 dimensions of product quality• Performance

– How well the product performs in comparison to how it was designed to perform

• Reliability– Likelihood that the product will

perform throughout its expected life

• Durability– The actual life expectancy of the

product• Conformance

– Does the product meet its specifications as designed

• Features– What different functions or tasks

can the product perform• Aesthetics

– Is the styling, color, workmanship pleasing to the customer

• Serviceability– What is the ease of fixing or

repairing the product if it fails• Perceived Quality

– Based on customer’s experience before, during and after they purchase a product

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Total quality management (TQM) is a philosophy focused on meeting customer expectations with respect to all needs, across all company functions, and recognizing all customers, both internal and external

• TQM’s basic conceptual elements are:– Top Management commitment and support– Maintaining a customer focus in product, service

and process performance– Integrated operations within and between

organizations– A commitment to continuous improvement

Total quality management

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Management standards have been established by the ISO in both quality and environment

• The International Organization for Standards (ISO) was formed after World War II

• ISO 9000—International Quality Standard– First one established in 1994– Currently transitioning to ISO 9000:2008

• ISO 14000—International Environmental Standard– First one established in 1998– Current one is ISO 14001:2004

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

ISO certified suppliers are frequently preferred by procurement departments

• They have to conform to an externally defined set of standards for quality and delivery of service

• They are usually more open to sharing supply chain information

• They welcome building relationships with their customers• They have formal processes in place for continual improvement of their

products, services, and processes• They are easier for procurement folks to initially qualify and periodically

audit– Certification is done by an external register agency– Firms have to be re-certified every three years

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Brand power is the measure of customer preference based on reputation, product quality and supply chain capabilities

• Volume is traditionally treated according to the principle of economy of scale– Average cost to produce product declines as

manufacturing volume increases– Particularly important when high fixed costs

are present

• Variety involves frequent product runs and high repetition of small lot sizes– Processes that can rapidly switch production

from one product to another while retaining efficiency are said to have economy of scope

Manufacturing perspectives

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Constraints interact with volume and variety to create realistic manufacturing plans– Capacity is how much can you produce in a given unit of time– Equipment considers how flexible it is

• Is one particular piece a bottleneck?– Setup/Changeover considers how quickly can you change from

one variety of product to another

• Leadtime is the measure of elapsed time between release of a work order to the shop floor and completion of all work on the product to achieve ready-to-ship status

Manufacturing perspectives continued

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Job shop creates a custom product for each customer• Batch process manufactures a small quantity of an item in

a single production run• Line flow process has standard products with a limited

number of variations moving on an assembly line through stages of production

• Continuous process is used to manufacture such items as gasoline, laundry detergent and chemicals

• Modifications of the above can create new options– Mass customization produces a unique product quickly and at a

low cost using a high volume production process

The four basic manufacturing processes

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Engineer to Order (ETO) is used when products are unique and extensively customized for the specific needs of individual customers

• Make to Order (MTO) relies on relatively small quantities, but more complexity– Requires much interaction with customer to work out design and specification– Usually shipped direct to customer

• Assemble to Order (ATO) is when base components are made, stocked to forecast, but products are not assembled until customer order is received – Manufacturing postponement practiced here

• Make to Stock (MTS) features economies of scale, large volumes, long production runs, low variety, and distribution channels

Manufacturing strategies should match market requirements

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

The choice of strategy determines which performance cycles the customer experiences

Figure 5.1 Manufacturing Strategy and Performance Cycles

Product Design Procurement Cycle Manufacturing Cycle Customer Delivery Cycle

ETOStrategy

MTOStrategy

ATO Strategy

MTPStrategy

Total Cycle Experienced by Customers.

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

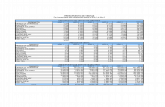

Product Variety

Volume Strategy Customer Leadtime

Job Shop Very high Very low ETO/MTO Very longBatch High Low ETO/MTO/

ATOLong

Line Flow Limited High ATO/MTP ShortContinuous Flow

Very limited Very high MTP Very short

Table 5.1Manufacturing process characteristics

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Total cost of manufacturing (TCM) includes:– Procurement and production activities– Inventory and warehousing activities– Transportation activities

• TCM generally expressed as cost per unit• Procurement and production costs go down

as volume goes up• Inventory and warehousing costs go up as

volume goes up• Transportation costs go down as volume goes

up, but level off at high volumes

Total cost of manufacturing

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

TCM per unit ranging across strategic alternatives

/MTS

Figure 5.2 Total Cost of Manufacturing

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Mass customization• Flexible manufacturing• Lean systems• Six sigma• Requirements planning• Design-for-manufacture• Design-for-logistics

Contemporary manufacturing developments

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

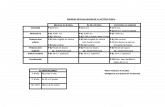

Manufacturing characterizations

Flexibility Economies of scale Responsiveness

Engineer to Order (ETO)

Make to Order (MTO)

Assemble to Order (ATO)

Configure to Order (CTO)

Make to Stock (MTS)

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Flexibility strategy defines the role that operations plays in the business and overall supply chain strategy

• Four Competitive Strategies– Mass Customization– Fast Lean Launch– Volume Response– Robust Operation

Flexibility-based strategies

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Manufacturing capability examples

• Mass Customization

• Fast, Lean Launch

• Mix/Volume Response

• Robust Operations

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

What is it?• Objectives, key capabilities

Where does it work?• Market, industry, technological characteristics

What does it take to succeed?• Resources and relationships• Priorities, processes, and practices• Cross functional interfaces• Metrics

For each strategy we’ll discuss:

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Individually customized products produced at the low cost of standardized, mass produced goods.

• Objective– Wide product menu with reasonable cost and OTD lead time– “On-Demand”, “To Order”, “Postponement”, “Agile Mfg”

• Examples: Dell, Cannondale, Cheesecake Factory, Knightly Tours

Mass customization: What is it?

Deliv

ered

Cos

t (or

Lea

d-Ti

me)

Product Customization

Conventional Demand-Supply Chain

MC Demand-Supply Chain

Standard Custom

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Market Characteristics:• Sufficiently large customer segment that values “translatable variety”

• Turbulent, dynamic market

• Unpredictable demand - but not entirely unpredictable!

• Little impact of regulation or other constraints (designer drugs?)

Product/Process Characteristics:• Modular or adjustable product building blocks

• Predictable components/functions interactions

• Standardized process/skill building blocks

• Reasonable lead times, steps, work content

Mass customization: Where does it work?

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Sense– Direct relationships with customers – demand management– Technologies: measurement, data capture, communication, CRM, POS

• Interpret– Technologies: imaging, data translation, configuration management,

CAD/CAE/CAPP– Product modularity and good configuration management

• Respond– Close relationships with supply chain elements (VI?)– Technologies: CAM, FMS, mixed model lines, digital tracking and control,

cellular mfg• Critical functional integration:

– Mktg-Sales-(Design)-Mfg

Mass customization: What does it take to succeed?

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Fast and reliable new product launch with few engineering changes

• Objectives– Overlapping ramps (up and down)– Reduced time to full scale production (“going vertical”)– High launch quality with few engineering changes required

Capability: Fast lean launch

Prod

uctio

n ra

te Conventional Launch

Lean Launch

Time

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Structural and Infrastructural Elements– Design–launch–build teams, DFMA, Process simulation, CE

• Production engrs and plant workers involved 36 months before launch (vs. 9 months before launch in old system)

– Hi fidelity (on-line) prototype and pilot production (release for tooling)– Adaptable plant hardware (e.g., conveyances, IS, …)– Manage varying conditions (product, process, geography) with

standardized launch process– Smart use of platform design and modularity strategies– Learning organization – ability to quickly develop and adopt new skills

and processes

Lean launch example: BMW

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Manage reaction to “discipline” imposed on product design

• Shape value system to add launch quality as a priority while preserving design flexibility

• Find manufacturing talent to make contributions in NPD

• Balance competing priorities of production vs. prototyping on the shop floor

• Manage critical functional integration: Design-Mfg

Lean launch: Key challenges

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Efficient response to seasonal demands (“chase” strategy)• Objectives

– Shift product mix and output over wide ranges with low inventories, cost, and response time

– Relatively flat total cost curve

Capability: Mix/volume response

Unit

Cost

, OTD

, etc

Conventional Demand-Supply Chain

Responsive Demand-Supply Chain

Production Volume

Deliv

ered

Cos

t (or

Lea

d-Ti

me)

Product Customization

Conventional Demand-Supply Chain

Responsive Demand-Supply Chain

Standard Custom

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Structural and Infrastructural Elements– Production, supply, channel management

personnel meet weekly– Scalable, flexible capacity

• Cross-trained, incentive-driven labor • “Tunable” factory – Teams reassign operators hour-to-hour, create recovery plans as

needed, Planners reassign personnel to other factories day-to-day, Mgmt transfers product build among factories season-to-season

• Flexible suppliers – Required to be able to increase shipments by 25% on 30 days notice, 50% in first 90 days of new product, VMI, production plans shared weekly, on-line consumption visibility

– Demand management – sales incentives, lead time promises

Mix/volume response example: Dell servers

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Improved aggregate planning models– Cost accuracy

– Model sophistication

– Smart uses of slack capacity; external sources of capacity (surge); temporary labor or overtime

• Complimentary products or activities (prototyping?)

• Labor for capital substitution

• Find proper “balance” in modularity and common building blocks

• Critical functional integration: Supply-Mfg-Sales

Mix/volume response: Key challenges

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Uniform performance over a wide variety of process conditions

• Objective:– Accommodate variations in input or resource characteristics with no

degradation in quality, yield, lead time, etc.• Examples: Kellogg’s, Furniture Mfg, MBA School

Robust operations: What is it?

Unit

Cost

, Def

ects

, etc

Conventional Demand-Supply Chain

Robust Demand-Supply Chain

Supply Variability

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• High variability in input material characteristics

• High variability in resource characteristics or availability

• Substitute materials or resources are possible

• Cost of materials is a high percentage of unit cost

Robust operations: Where does it work?

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Sense and accommodate– High level of process knowledge – understand

process physics

– High level of process capability

– Process flexibility – ability to make adjustments appropriate to incoming requirements

• Critical functional integration:– Purchasing-Process Engrg-Mfg

Robust operations: What does it take to succeed?

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Comparative manufacturing modelsMass

CustomizationFast Lean

LaunchMix/Volume

ResponseRobust

Operations

Engineer to Order

Make to Order

Assemble to Order

Configure to Order

Make to Stock

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Lean is a philosophy of manufacturing that emphasizes the minimization of the amount of all resources (including time) used in the operation of a company

• Defining principle is the elimination of “waste”

Lean systems

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Produce only the products that customers want

Produce products only as quickly as customers want them

Produce products with perfect quality

Primary objectives of lean systems

Produce in the minimum possible lead times

Produce products with features that customers want and no others

Produce with no waste of labor, materials or equipment

Produce with methods that reinforce the occupational development of workers

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Six sigma approach is to identify sources of variability and then systematically reduce them

• The six sigma goal is to achieve a process standard deviation that is six times smaller than the range of outputs allowed by the product’s design specification

Six sigma quality concepts

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Example of a six sigma quality level

• Produces defect free product 99.74 percent of the time

• 66,807 defects per million parts produced

• Produces defect free product 99.99966 percent of the time

• 3.4 defects per million parts produced

Three sigma quality level

Six sigma quality level

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Resources must be procured, positioned, and coordinated as needed to support the manufacturing strategy selected

• Four approaches to achieve this are:– Just-in-time (JIT)–Materials requirements planning (MRP)–Design for logistics–Performance based logistics

Logistical interfaces

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Just-in-time only produces to a customer order (ATO, MTO)

• Purchased materials and components arrive at the manufacturing or assembly point just at the time they are required for the transformation process

• Raw material and work in process inventories are minimized

• Demand for materials depends on the finalized production schedule

• Lot sizes are as low as one unit• Close cooperation with suppliers is

essential!

Just-in-time (JIT) interfaces

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• For more complex manufacturing (MTO, ETO) where large numbers of components or assemblies are used to produce a final product

• Procurement has a key role in insuring all the components are obtained on time to make an end item– Key information requirement is the bill of

materials (BOM)• Planning sometimes spans multiple

manufacturing locations (e.g. Boeing Dreamliner)

Materials Requirements Planning (MRP) interfaces

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Design-for-assembly – focuses on minimizing the number of parts and on easing assembly processes.

• Design-for-product-servicability – focuses on easing the disassembly and reuse of product components.

• Design-for-six-sigma – systematically evaluates the consistency with which a good or service can be produced or delivered given the capabilities of the processes used.

Design for manufacture

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Design for logistics includes the requirements and framework for logistical support in the early phases of product development

• Considers– What we are going to make– How we are going to make it– What logistics capabilities do we need– How we are going to integrate our

suppliers into the process– Any subassembly manufacture by

suppliers– The need for outsourcing of some

parts or assemblies

Design for logistics interfaces

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

• Initiated by US Department of Defense to purchase performance outcomes instead of individual transactions defined by product specifications

• Government specifies desired outcomes and lets suppliers determine the best way to meet those requirements

• Currently limited to government purchasing but business organizations are expected to adopt the practice

Performance based logistics interface

Copyright © 2013 by The McGraw-Hill Companies, Inc. All rights reserved.

McGraw-Hill/Irwin

Table 5.2 - Strategic integration framework